USG 2 Ultrasonic Generator encoder model generator

Our ultrasonic Generators are able to run any frequency 15 kHz, 20 kHz, 22 kHz, 23 kHz, 25 kHz, 28 kHz, 30 kHz, 35 kHz, 36 kHz, 40 kHz, 50 kHz, 60 kHz, 70 kHz, 80 kHz.USG 2 ultrasonic generator assembly systems are available from 400-3300 Watts output power. This enables operating in continues, distance, time, energy or peak power welding modes, depending on the control level selected. Multiple modes are valuable for applications requiring a high level of process control and weld quality.

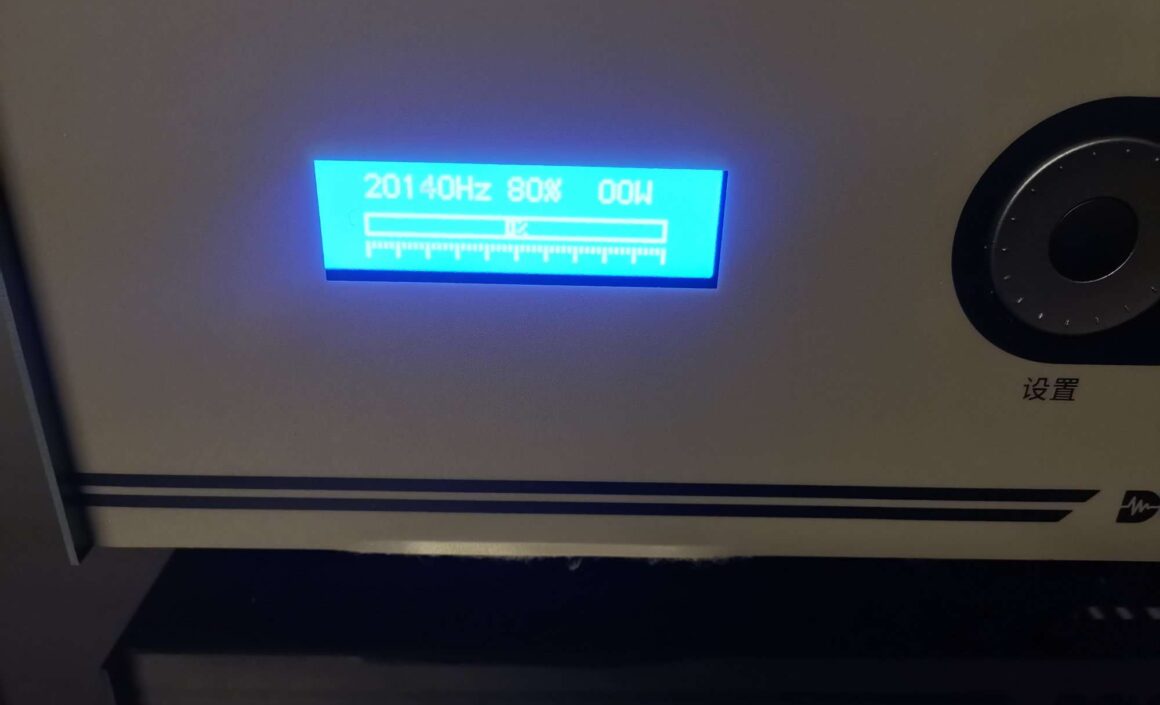

In addition, the amplitude can be regulated from 50-100% from the front panel or via a remote 5-10 volt signal. All systems include the enhance digital processor PID / PLL frequency control with a frequency window + – 1000 Hz providing enhanced performance, consistency, and reliability.

It also includes a user interface with a LARGE LCD display designed for ease of use in setup, operation, and troubleshooting. The system also has enhanced data capabilities for configuration and information management.

These systems are designed for use in manual, semi-automated, or fully automated environ¬ments. An actuator may be connected and controlled direct from the generators 9 pole Sub-D connector.

KEY FEATURES

User Interface/Process Controls

• Size L435 x W260 x H140, Weight 6.8 kg

• 1 Ms sampling rate of data provides Superior performance, consistency, and control.

• Multiple welding modes dependent on control level, time, energy, peak power, and ground detect. Energy is settable in increments of 0.1 watt. Peak power can be set in increments of 1 watt %.

• Amplitude 50-100% — can be controlled from the front panel or from remote with a 5-10 volt signal.

• Expanded process control limits, trigger range, energy compensation, provide more choices in application setup.

• Expanded quality monitoring limits to identify “reject” parts.

• Built-in digital amplitude control – for fine-tuning of critical applications, because amplitude is the most important variable in ultrasonic welding. The setting has a range of 50% to 100%.

• True alarm messages for ease of troubleshooting, with links to additional information.

• Self-diagnostics – visual, audible, and logic output alarms.

• Built-in frequency and memory diagnostics for simplified troubleshooting of the converter/booster/ horn stack.

• Alarm and cycle counters are built in for tracking production; works via a real time clock.

• Built-in ground detect with scrub / Afterburst time delay up to 30 seconds to increase tooling and converter life in cut and seal applications.

• Selectable pre-triggering or trigger by time.

• Fully voltage and current protected – able to cut cable under full load, without damaging the generator.

• Password protection feature for lock-out of unauthorized process changes

Power Supply

• Line / Load Regulation – Corrects for variations due to power line fluctuations and varying load conditions.

• Auto tune plus Memory – Provides fully-automatic tuning in a range of ±1000 Hz going up from 19.000 for 20 kHz horns, ±1000 Hz 29 kHz for 30.000 Hz horns, and ± 1000 Hz around 39.000 kHz for 40 kHz horns, and stores the horn frequency during initial start up test.

• IP 65 the generator can be delivered as IP65, for hard environment production.

• System Protection Monitor (SPM) Five levels of power supply protection are provided: 1) phasing, 2) over voltage, 3) over current.

Series USG400 USG800 USG1100 USG1500 USG2000 USG2500 USG3300

Output Power 400 watt 800 watt 1100 watt 1500 watt 2200 watt 2500 watt 3300 watt

Line voltage 180-250 VAC 180-250 VAC 180-250 VAC

Max currect 7 Amps max 10 Amps max 13 Amps max 16 Amps max

Frequency 14-150 kHz 14-40 kHz 14-25 kHz 14-22 kHz 14-22 kHz

Max cycle rate 300 cycle parts per minute

Ambient temp range 41-122° F (5-50°C)

Ultrasonic generators comes under following names:

Ultrasonic welding Generator, Ultraschall schweiss generator, Ultraschall schweissgenerator, Ultraschall generatoren, Ultrasonic Generator, Ultraschall Generator, Generador de ultrasonidos, Gerador de ultra-som, Ultrasonic Cutting Generator, Ультразвуковой генератор сварочный, Ultradźwiękowy Generatory spawanie, Générateur de soudage par ultrasons, Générateur à ultrasons coupe l’alimentation, Ultrasonic food cutting Generator, Ultradźwiękowy Generator cięcie żywności, Ультразвуковой генератор резки пищи, Générateur de soudage par ultrasons, ultrasonic welding generator, saldatura generatore di ultrasuoni, Ultradźwiękowy generatory spawalniczy, gerador de soldagem ultra-sônica, ультразвуковой генератор сварочный, generador de soldadura por ultrasonidos, Ultraschallschweißen generator, Ultrasons générateur de soudage de plastique, generatore di saldatura ad ultrasuoni di plastica, Ultradźwiękowy generatory spawanie plastiku, gerador de soldagem ultra-sônica de plástico, ультразвуковой сварки пластиковых генератор, generador de ultrasonidos de soldadura de plástico, Ultraschall Kunststoffschweißen Generator, Ultrasonic plastic welding generator, ultrasonic welding generator, Ultraschall schweissen generator, Ultraschallschweissen generator, ultrasonique générateur, ultrasonique coupe générateur, ultrasonique nourriture coupe générateur, Zgrzewarki wykorzystywane, Ultradźwiękowy generatory, Ultraschallgenerator ,ultraschallgeneratoren, ultraschall schweissen generatoren, ultrasonic food cutting generator,